The M-19 Story

Test Flight of the Mooney M-19

You may recall that the M-19 was a specially modified M-18C-55 which

Mooney developed as a counter-liaison aircraft they called the "Cub-Killer." It

featured a 90 h.p. engine with a Flottorp constant speed propeller and .30

caliber machine guns in the wings. No one seems to know where the M-19 is now --

even photos of the plane are as rare as hens' teeth. Only stories remain. Here

is a good one from long-time Mooney man, Bill

Wheat....

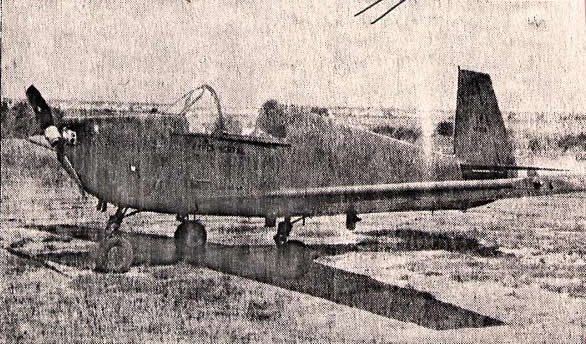

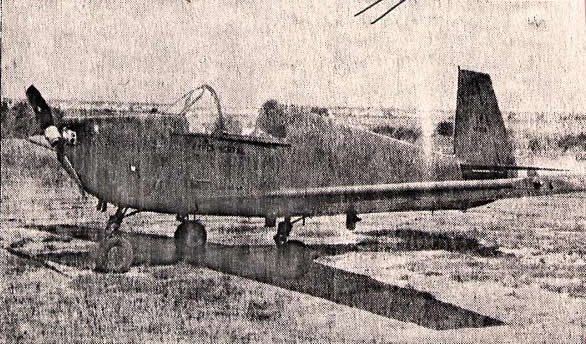

"The photo is definitely the M-19. The pilot is

Bill Taylor [Mooney's general manager]. Due to the quality of

the picture I cannot be certain as to whether it is as presented to the Military

or repainted and cleaned up as a company run-about. The original was a dull

olive-drab all over and was as ugly as all-get-out."

"The photo is definitely the M-19. The pilot is

Bill Taylor [Mooney's general manager]. Due to the quality of

the picture I cannot be certain as to whether it is as presented to the Military

or repainted and cleaned up as a company run-about. The original was a dull

olive-drab all over and was as ugly as all-get-out."

"Taylor's first flight lasted about an hour and a half. Normally, the first

flight of a proto-type was about 15 minutes. Everyone was in front of the

factory and getting worried.

When he finally taxied up and got out, someone asked him what he was going

to name it. He stood on the wing for a moment and finally answered, 'Old

Puss.'

Al Mooney asked why and Bill replied, 'It's the only thing

I can think of that looks so bad and feels so good!'"

27 October, 2000

Development history of the M-19

The following articles are from the files of Tony Terrigno who acquired

the material from Glenn Bell. The first is a reprint of an undated document

prepared by Mooney Aircraft outlining the rationale for the development of the

M-19:

MOONEY AIRCRAFT, INC.

Wichita – Kansas

THE MOONEY MODEL M-19 AIRCRAFT.

1. PURPOSE.

To develop and evaluate the possibilities of a small, armed, single-place

aircraft for use by the Armed Forces in the following specific functions:

A. As direct and close support of ground troops beyond the support now

given.

B. To destroy enemy light observation and artillery control aircraft.

2. INSPIRATION FOR DEVELOPMENT.

As a result of many informal demonstrations of our civil Model M-18

aircraft to Air Force, Army Aviation and other military flying personnel, it was

repeatedly suggested that the very superior low-level flight and maneuverability

characteristics would have great value in connection with the above functions

provided the aircraft could be armed with machine guns and light rockets, while

maintaining these characteristics.

A careful and thorough design study by MOONEY AIRCRAFT in late 1950 proved

that the desired characteristics could be maintained while providing for a

substantial military load of guns, ammunition and light rockets, The resulting

aircraft was designated as our Model M-19, and was substantially a completely

new design.

3. DEVELOPMENTAL RESPONSIBILITY.

On January 2, 1951, at a conference at Army Field Force headquarters, Fort

Monroe, Virginia, with Colonel Boyd and Lt. Col. John W. Oswalt, it was

determined that if MOONEY AIRCRAFT developed such an aircraft upon its own

initiative and at its own expense, Army Aviation in turn would give it an

informal but complete evaluation at the Fort Sill Air Training Base. The

management of MOONEY AIRCRAFT decided to proceed upon this basis, and the

prototype was constructed, flight tested, and presented at Fort Sill on April 5,

1951.

4. EVALUATION TESTS AND DEMONSTRATIONS.

During the year 1951, the following tests and demonstrations were

accomplished:

A. Fort Sill, Oklahoma.

By authority of Colonel Hopkins, Commanding the Air Training Department,

and under the direct supervision of Lt. Col. D. E. Condon, Engineering Officer,

an extensive and satisfactory evaluation of this aircraft was conducted between

April 5th and April 24th, 1951. During this evaluation all

phases of low-level flight were investigated and it was demonstrated that this

aircraft could hit targets with both rocket and machine gun fire very

effectively under simulated battle conditions.

We understand that a report on these tests was forwarded to Army Field

Force headquarters at Fort Monroe, and we were told that the report was

favorable. It was stated that the aircraft had possibilities as a spotting

aircraft. It was understood that these officers, while having no procuring

authority, were favorable towards recommending a small procurement for further

evaluation and service test. Several improvements, non-basic in nature, were

also recommended from these tests, in the event of procurement.

Many officers flew the prototype at Fort Sill. The officers actually

responsible for the evaluation were: Lt. Col. D. E. Condon. Captain Neely R.

Brown. Captain William R. Dodd. We consider all proceedings to be in keeping

with the informal understanding at the basic conference.

B. Fort Bragg, North Carolina.

On May 17, 1951, while awaiting some word from Fort Monroe regarding the

Fort Sill tests, an informal visit was made to Army Aviation Board No. 1 at Fort

Bragg. Colonel Compton, President of Board No. 1 authorized a machine gun firing

demonstration under the supervision of Major Thomas E. Haynes. Major Haynes was

quite frank in telling us that the pressure from prior projects would prevent

setting up much of a demonstration, and while most of the Board pilots were

checked-out in the aircraft, little serious low-level flying was done.

On May 24, 1951, several slow passes over the target were made by Captain

Thomas E. Hall with a good percentage of hits with machine guns, but without

evasive action or tactics being practiced. Numerous officers witnessed this

demonstration , among them being Lt. Col. Oswalt from Fort Monroe, but we felt

that this demonstration was of negative value because of poor preparation and

apparent lack of interest.

C. Fort Meade, Maryland.

An informal demonstration was made at Fort Meade on May 30, 1951. The Air

Officer for the 2nd Army, Lt. Col. Harry K. Bayless, and two members

of his staff flew the aircraft. Colonel Bayless expressed an informal opinion

that the aircraft had a place in Army Aviation.

D. Fort Monroe, Virginia.

Our pilot put on a flight demonstration at Fort Monroe, Virginia on May 31,

1951 before Colonel Boyd and Lt. Col. Bruce B. Caulder, in the absence of

Colonel Oswalt. Following this demonstration Colonel Caulder gave us to

understand, in an informal manner, that while many officers were favorable

towards procurement and development of this type aircraft, there were reasons

which he could not disclose preventing procurement or even discussions of such a

project.

E. U. S. Marine Corps Air Station, Quantico,

Virginia.

After the apparent stone-wall situation reported above, we contacted

Colonel Montgomery of the Marine Corps at the Pentagon and he made arrangements

for a demonstration of our aircraft at the Air Station at Quantico. This

demonstration was under Lt. Col. Mickey, Deputy President of the Equipment

Board, with detail arrangements being handled by Captain Victor Armstrong.

In addition to the Navy and Marine officers present, officers from Army

Ordnance, Army Aviation, National Guard and other military services witnessed

the demonstration on September 4, 1951. Our pilot did the flying, and both still

photographs and moving pictures were made of this demonstration by the USMC.

Both machine gun and rocket firing was done, and the entire demonstration was

conducted at low-level, using evasive tactics and maneuvers to simulate battle

conditions and bring out the possibilities of this concept.

As a result of this demonstration, the Commandant, USMC, shortly afterwards

authorized a project for the Equipment Board to study this concept and tactics.

Until the study is completed, we will not know the results of this effort. We

feel that a favorable answer might emerge as a result of the above fine

demonstration, unless a stone-wall situation like that of the Army appears.

5. DISCUSSION AND SUMMARY.

From the above, it is apparent that it has been impossible to obtain much

of an idea as to the real impact of this aircraft upon the procuring

authorities. Rather, it appears that perhaps the basic concept is a point of

controversy. When the original informal set of requirements were set down, we

quickly proved we could produce an aircraft fully meeting those requirements. By

the same token, we can also efficiently meet a similar set, if ones were

issued.

We strongly feel that the present requirements are sound, as shown by the

Fort Sill and Quantico tests. Any requirement for higher speed would quickly

nullify the low-level capabilities, due to limitations of the human body, as we

have discovered and can easily prove. We strongly feel that further tests of a

single aircraft, or paper considerations, cannot prove or disprove the value of

an operation of this kind, which primarily depends upon group tactics and

team-work for full success. We believe that an evaluation program involving the

use of a suitable quantity of these aircraft is the next logical step in the

ultimate evaluation. Finally, we earnestly believe that the United States can

ill-afford to incompletely evaluate any weapon which might improve our position

regarding man-power.

Attachment: Brief Specifications – Model M-19. (See below)

MOONEY AIRCRAFT, INC.

Specification No. 12

MODEL SPECIFICATION - PRELIMINARY 10

May 1951

AIRPLANE, LIAISON, COUNTER.

MOONEY MODEL M-19.

A. APPLICABLE SPECIFICATIONS

A-1. The following publications of the issue specified are applicable to,

and form a part of, this specification.

U.S. Civil Aeronautics Regulation, Part 03, Edition of 15 December 1946

as revised up to the date of this specification.

Mooney Design Study, Informal. Model M-19, dated December 1950.

B. TYPE.

B-1. This specification covers the following airplane:

| Manufacturer's Name and Model No. |

Mooney M-19 |

| Number of places |

One |

| Number of engines |

One |

B-2. This airplane will be equipped with the following engines:

| Name and Type |

|

C90-14 |

|

|

|

| Horsepower Rating: |

|

|

|

|

|

| Normal |

90 |

Altitude |

Sea Level |

R.P.M. |

2475 |

| Take-off |

95 |

Altitude |

Sea Level |

R.P.M. |

2625 |

| Propeller gear ratio |

|

Direct drive |

|

|

|

B-3. This airplane will be equipped with a Flottorp constant-speed

propeller as specified in paragraph S-3, page 7.

B-4. The intended prime tactical mission of this airplane is use as a

counter-weapon against liaison type aircraft. It is also intended for use as a

low-level close support aircraft against small dispersed objectives and enemy

personnel.

C. MATERIALS AND WORKMANSHIP.

C-l. Materials and workmanship, processes and finishes shall be equal to

or superior to those prevailing in high grade aeronautical practice, in

accordance with applicable specifications approved for this airplane by the

Civil Aeronautics Administration.

C-2. It is intended that non-critical and non-strategic materials be used

in the fabrication of this airplane to the greatest extent possible.

D. GENERAL REQUIREMENTS

D-l. The Mooney Model M-19 airplane covered by this specification shall

be designed and constructed in accordance with publications listed in Section

"A" of this specification, and as hereinafter-set-forth.

E. DETAIL REQUIREMENTS.

E-1. Performance, Crew, Equipment and

Furnishings: The performance, crew, equipment, and furnishings of this

airplane will conform to the following:

E-la. Performance at design gross

weight, NACA Standard Air.

| (1) High speed at sea-level, m.p.h. |

150

|

| (2) Operating speed at sea-level, m.p.h. |

135

|

| (3) Endurance at operating speed, hours, |

4.0

|

| (4) Range at operating speed, miles, |

540

|

| (5) Rate of climb, f.p.m., (1st minute), |

1000

|

| (6) Service ceiling, feet, |

17100

|

| (7) Absolute ceiling, feet, |

19000

|

| (8) Landing speed, m.p.h |

45

|

| (9) Minimum speed, (maintain constant altitude with full control),

m.p.h. |

50

|

| (10) Distance to take-off and climb 50 ft., feet, |

750

|

| (11) landing over 50 ft. and stop, feet, |

700

|

E-1b. Crew. Provision for a pilot

only shall be made in this airplane

(See paragraph E-2e (4)(a), page 6.

E-1c. Armament. Provision for the

following alternate armament shall be made in this airplane:

E-1c (l). One U. S. Army Model M1919 A4 30 caliber light air-cooled

machine gun shall be mounted in each wing. Provision for loading a suitable test

quantity of ammunition for each gun will be made. Provisions for charging the

gun from the cockpit shall be made. Selective switches and a trigger switch on

the control stick shall be provided.

E-lc (2). Mark 5 zero-length rocket launchers shall be mounted beneath

each wing. Launchers shall be so arranged that SCAR sub-caliber practice rockets

may be mounted. Launchers shall be capable of supporting HVAR rockets. Provision

for selective switches and separate control switches on the stick shall be made.

An arming switch shall be provided.

E-lc (3). A Mark 9 illuminated sight shall be mounted in the cockpit on a

gimbal mounting in line with the pilot's left eye. Provision for quick removal

and replacement of the sight shall be made.

E-ld. Equipment. The instruments and

other required equipment as specified in applicable CAA documents shall be

installed. Additional equipment required by the missions to be performed shall

be installed or provided for as follows:

E-ld (l). Communications Radio. A

Bendix Model PAT-50A VHF transmitter with crystals for CAA range and Tower

communication shall be installed. A Bendix Model PAR-70A low-frequency receiver

shall be installed.

E-ld (2). Tactical Radio. Provisions

shall be made for the quick installation of a BC-1335 FM tactical receiver and

transmitter. A switch shall be so arranged that the microphone and headphones

may be used with either radio equipment at will.

E-1d (3). Position lights. CAA

approved position lights shall be installed on this airplane.

E-1d (4). Shoulder Harness. Shoulder

harness of the reel-type shall be installed in this airplane.

E-1c. Furnishings. Furnishings shall

be as specified by CAA applicable requirements and as hereinafter specified.

E-2. Airplane.

E-2a. Airplane Weight and

Balance.

E-2a. (1). Weights. The following weights are applicable to this

airplane.

| Weight Empty |

|

|

800 lbs |

| Useful Load |

|

|

650 lbs |

|

Pilot and parachute |

190

|

|

|

Oil (4 qts.) |

8

|

|

|

Fuel (22 gal.) |

132

|

|

|

Military Load |

320

|

|

| Design Gross Weight |

|

|

1450 lbs |

E-2a (2). Balance. The following

center of gravity limits are applicable to this aircraft. Limits are based on

extended landing gear.

| Most forward loading, aft L.E. MAC |

11.28% MAC |

| Host rearward loading, aft L.E. MAC |

20.67% MAC |

E-2b. Flight Tests. This airplane

shall conform to all flight requirements under applicable CAA regulations except

in such cases where the following requirements take precedence.

E-2b (1). Control and handling characteristics shall be adequate for

normal take-offs and landings on narrow roads, runways, or strips in crosswinds

up to 30 m.p.h. at 90 degrees to the path. It shall be possible to operate

normally on roads of moderate curvature.

E-2b (2). Minimum lateral control effectiveness shall be acceptable to

the procuring agency.

E-2b (3). The airplane shall be controllable at the stall with normal

control motions, in cruising, glide, landing, or power approach

configurations.

E-2b (4). It shall be possible, without external assistance, to handle

and taxi this airplane in a normal manner in winds up to 50 m.p.h. velocity in

any direction.

E-2c. Structural Requirements. This

airplane shall satisfy all structural requirements of the applicable CAA

requirements except in such cases where the following requirements take

precedence.

E-2c (l). Load factors.

| Positive limit load factor) |

4.0 |

| Negative limit load factor |

-1.6 |

E-2c (2). Design structural

speeds.

| Cruising speed, m.p.h. |

160 |

| Dive speed, m.p.h. |

215 |

| Placard dive, m.p.h. |

193 |

| Maneuvering, m.p.h. |

127 |

| Flaps extended, m.p.h. |

91 |

E-2d. Arrangement. The size, weight,

and arrangement shall be kept as small as possible consistent with the missions

to be performed, to permit maximum ease of ground handling by one man, to

facilitate operation from roads, and to result in maximum performance for the

Type and Class.

E-2e. Detail Design.

E-2e (l). Wing Group.

E-2e (l)(a). Airfoil Section

Designation:

Root NACA 0015 Tip NACA 4410

E-2e (1) (b). Dimensions

| Wing Area |

95 sq. ft. |

| Span |

26 ft. 10 in. |

| Root Chord |

4 ft. 8½ in. |

| Tip Chord |

2 ft. 4 in. |

| Incidence: Root |

4.0 deg. |

| Incidence: Tip |

-1.0 deg. |

| Dihedral |

5.5 deg. |

| Sweepback |

Straight leading edge. |

E-2e (l) (c). Wing Construction.

Wing shall be of the full cantilever type in one piece with a single shear spar

monocoque stressed skin construction. Spar shall be spruce or poplar flanges

with diagonal mahogany plywood webs. The wing shall be covered with diagonal

mahogany or poplar plywood. Suitable spruce or plywood stringers and ribs shall

be incorporated for structural integrity. Provision shall be made for retracting

the main gear into the wing. The wing shall be fabric covered and fire-resistant

finish shall be required.

E-2e (2). Control Surfaces.

E-2e (2) (a). Ailerons:

| Area: |

6.62 sq. ft. |

| Angular Movements: |

Up 20 deg. Down 10 deg. |

| Type of balance: |

Weighted overhung balance outboard of tip |

| Tabs: |

None |

E-2e (2) (b). Horizontal Tail

Surfaces.

| Area |

18.09 sq. ft. |

| Span |

8 ft. 5 in. |

| Maximum Chord |

2 ft. 7 ½ in. |

| Stabilizer. |

|

|

Area |

12.15 sq. ft. |

|

Normal setting |

Adjustable |

|

Angular movement |

Up 2 deg. Down 4 deg |

| Elevators. |

|

|

Area |

5.94 sq. ft. |

|

Angular Movements |

Up 25 deg. Down 13 deg. |

|

Type of balance: |

Weighted overhung balance at tip |

| Tabs: |

None |

E-2e (2)(c). Vertical Tail

Surfaces

| Area |

7.66 sq. ft. |

| Span |

3 ft. 3 in. |

| Maximum Chord |

3 ft. 2 in |

| Fin. |

|

|

Area |

4.87 sq. ft. |

|

Normal setting |

1 deg. left |

|

Angular movement |

None |

| Rudder. |

|

|

Area |

2.79 sq. ft. |

|

Angular movement |

Left 23 deg. Right 25 deg. |

|

Type of balance |

Weighted overhung balance at tip |

|

Tab: |

None |

E-2e (2)(d) Wing Flaps.

| Area |

10.54 sq. ft. |

| Type |

NACA slotted |

| Percent of wing span effected by flaps |

70% |

| Maximum deflection |

40 deg. |

E-2e (2)(e). Construction of Control

Surfaces. Ailerons shall have steel tube spar with sheet steel rib

structure, fabric covered. Fin and Stabilizer shall be of full cantilever

stressed skin wood structure, with fabric cover. The elevators and rudder shall

have a steel tube spar with sheet steel rib structure, fabric covered. The flaps

shall have a steel tube spar with sheet steel ribs, fabric covered.

Fire-resistant finish shall be applied to all surfaces.

E-2e (3). Control System.

Conventional stick and rudder pedal control shall be provided. Aileron and

elevator controls shall be direct push-pull tube linkage. The rudder control

shall be aircraft flexible cable.

E-2e (3)(a). Brake and Nose Wheel

Control. The brakes shall be hydraulic and operated by separate brake

pedals mounted on the rudder pedals. The nose gear shall be steerable, and

operated by the rudder pedals through direct push-pull tube linkage.

E-2e (3)(b). Stabilizer and Flap

Control. The longitudinal trim on this airplane shall be accomplished by

means of an irreversible control at the cockpit actuating the adjustable

stabilizer through direct push-pull tube linkage. The wing flap control shall be

so linked in with the trim control that the final "Nose-up" trim setting shall

coincide to the fully deflected flap position. The trim speed shall remain

approximately constant in the flap operating range.

E-2e (3)(c). Landing Gear Retraction

Control. The landing gear shall be retracted by means of a lever arm on

the right side of the cockpit. Positive locks in both retracted and extended

positions shall be provided. The landing gear shall be approximately balanced by

steel spring units to result in a minimum effort being required for operation.

The lever shall serve as a gear position indicator. Both visual and aural

warning devices shall be installed to prevent the possibility of inadvertent

gear-up landings.

E-2e (4). Body Group. The body

group shall consist of the fuselage with a detachable engine mount and rear

section, and shall include accommodations for the crew. The wing, tail surfaces,

and nose gear shall attach to the fuselage.

E-2e (4)(a). Fuselage: Maximum

cross-section: Height 50 in. Width 30 in. The forward fuselage structure shall

comprise the cockpit section and shall be an "island structure" of steel tubing,

with aluminum alloy sheet covering. This structure shall have structural

strength in excess of the specified air and ground load criteria to result in

crash protection for the pilot. The engine mount shall be of welded steel tube

construction and shall be detachable at the firewall. The rear fuselage section

shall be a stressed skin plywood cone with four longitudinal stringers and

stiffened by plywood stiffener rings. The cone shall have fabric covering and a

fire-resistant finish. The cockpit shall have a standard military seat and belt

for the pilot, and shall have sufficient room for a pilot in heavy winter gear

to accomplish the required missions. A removable sliding enclosure will be

installed which permits unrestricted vision for the pilot through 360 degrees in

a horizontal plane. The pilot's eyes shall not be located aft of the wing

leading edge. The windshield shall afford adequate vision for the low-level

mission basic to the Type. A flat panel shall be incorporated for forward vision

in such a manner that bullet-proof material may be later installed. The hatch

shall have a quick release system for emergency egress. The firewall shall be of

suitable material and construction. The reel-type shoulder harness shall be

suitably anchored to the structure. Provision for all required equipment and

controls shall be made.

E-2e (5). Engine Cowling.

The engine cowling shall completely enclose the engine, and shall be quickly

removable to such an extent as will readily allow inspection or servicing of the

engine and accessories. The cowl shall be mounted on the engine mount and

fuselage with suitable brackets. Cooling baffles of the full pressure type shall

be installed.

E-2e (6). Alighting Gear. The

alighting gear shall be the tricycle type with a nose wheel ahead of the C.G.

and the main wheels aft of the C.G. and shall be fully retractable.

E-2e (6)(a). Main Landing Gear.

Type of gear: Retractable with rubber shock units incorporating friction rebound

control. No air or oil shall be used in the shock units, for minimum maintenance

considerations. 5.00x5 low pressure tires shall be mounted on wheels with

hydraulic brakes. Major dimensions: tread, 5 ft. 1 in. Over-center locks in

conjunction with the cockpit lever lock shall position the gear in the extended

position.

E-2e (6)(b). Nose landing Gear. Type of gear: Retractable with rubber

shock units incorporating friction rebound control. No air or oil shall be used

in the shock units, for minimum maintenance considerations. 5.00x5 low pressure

tire shall be mounted on a wheel without a brake. Major dimensions: Distance

ahead of main wheels, 4 ft. 0-3/4 in. An over-center look in conjunction with

the cockpit lever lock shall position the gear in the extended position. The

gear shall be steerable through the rudder pedals. Provision for centering the

gear automatically in the retracted position shall be made. The gear shall

attach to the forward fuselage structure at the firewall, and no landing gear

loads shall be carried by any engine mount member.

E-2f. Materials - Finishing and

Processes.

E-2f(l). The wings, fuselage, and empennage of this aircraft shall

be camouflage green. Identification markings shall be in accordance with

applicable CAA requirements and shall be black. The finish shall be of the

fire-resistant type.

E-3. Propeller Installation. A

propeller conforming to the following characteristics shall be installed on this

airplane.

| Propeller Manufacturer's Name |

Flottorp Manufacturing Co. |

Type

|

Constant-speed |

Diameter

|

65 inches. |

Number of blades

|

Two |

Hub Model No.

|

65F |

Blade Model No.

|

R003 23465T |

Type of Control

|

Automatic electric |

Flight Research Eng. Corp.

|

|

| Minimum clearance: |

|

| In plane of propeller discs: |

|

To ground, static position

|

14 inches |

| Normal to plane of propeller disc: |

|

To engine cowl

|

4 inches |

To wing leading edge

|

47½ inches |

To nose wheel

|

18 inches |

E-4. Power Plant Installation. The

engine shall be mounted on the detachable engine mount by means of the rubber

vibration dampener units supplied with the engine.

E-4a. Engine. This airplane shall

be equipped with one Continental Motors Corporation engine Model C90-14

conforming to Continental Specification No. 1265-W and Civil Aeronautics

Administration Type Certificate No. 252.

E-4b. Lubrication System. The

lubrication system shall consist of a sump tank of 4 quarts nominal capacity

mounted integral with the engine.

E-4c. Cooling System. The engine

shall be direct air cooled by the use of full pressure type baffles. An oil

cooling radiator shall be mounted directly on the engine.

E-4d. Fuel System. The fuel system

shall have one aluminum tank of 22 gallons capacity mounted in the fuselage aft

of the cockpit, connected to the carburetor through suitable lines, valve,

strainer, the engine fuel pump, and a hand pump.

E-4e. Engine Control System. The

throttle control shall be a quadrant type with a flexible control linkage. The

carburetor heat control and the manual mixture control shall be flexible control

units.

E-4f. Exhaust System. The exhaust

system on this airplane shall consist of a corrosion-resistant manifold of the

cross-over type, having 360 degree exhaust spacing in each leg. Exhaust outlets

shall be at the bottom of the engine cowl near the right side. A carburetor air

heater shall be included.

E-4g. Engine Air Intake System. The

cold air intake and the hot air duct from the manifold heater shall be connected

to a suitable valve assembly so that the temperature of the intake air can be

controlled. An air filter shall be incorporated at the cold air inlet. The hot

air inlet shall be located in a sheltered position.

E-5. Armament installation. The

following provisions shall be made for installation of armament in this

airplane:

E-5a. Machine Guns. In each wing

provisions for mounting a U.S. Army Model M1919 A4 30 caliber light air-cooled

machine gun shall be made. Trays for a test quantity of ammunition shall be

provided. Suitable ejection chutes for links and cases shall be installed.

Solenoids for operating the gun triggers shall be provided. A flexible control

from the cockpit shall be provided for each gun to operate the charging handle.

Provision for a cooling blast of air on the gun barrel shall be made. An

adequate inspection panel shall be provided for installation, servicing, and

removal of each gun. The standard gun shall not require alteration for this

installation, except that the front sight may be removed.

E-5b. Rocket Launching

Installation. Navy Mark 5 zero-length rocket launching installations

shall be installed under each wing Suitable sheet metal panels shall cover the

underside of the wing and flaps in the vicinity of this installation.

E-5c. Sighting Installation. The

gimbal mount for the Navy Mark 9 illuminated sight shall be mounted from the

windshield frame by means of a small tubular tripod. The installation shall be

quickly removable.

E-6. Equipment Installation. All

equipment and instruments shall comply with CAA requirements and shall be equal

or superior to high grade commercial practice.

E-6a. Instruments and Navigation

Equipment.

E-6a(l). Instruments. The

instrument board shall be constructed of aluminum alloy sheet, and shall be

mounted at the base of the windshield.

E-6a(l)(a). Flight Instruments.

The following flight Instruments shall be provided: Airspeed Indicator,

Sensitive Altimeter, Compass, and Turn and Bank Indicator.

E-6a(l)(b). Engine Instruments.

The following engine instruments shall be provided: Tachometer, Oil thermometer,

Oil Pressure Gauge, Fuel Pressure Gauge.

E-6a(l)(c). Miscellaneous

Instruments. The following miscellaneous instruments shall be provided:

Ammeter, Fuel-level Gauge, and Suction Gauge.

E-6b. Electrical Installation.

E-6b(l). Generator. An engine

driven generator having a 15 ampere charging rate shall be installed. A voltage

control unit shall be included with the generator installation.

E-6b(2). Battery. One 12 volt

aircraft storage battery, located aft in the fuselage shall be provided.

E-6b(3). Starter. An electric

started of the direct cranking type shall be installed and shall be operated by

a manual control at the instrument panel.

E-6b(4). Lighting. CAA approved

position lights shall be installed.

E-6b(5). Switches. A battery

disconnect switch shall be provided as close to the battery as practical. A

selective type magneto switch shall be provided. Selective switches shall be

provided for each gun and rocket launching installation. An arming switch for

the rocket launching installation shall be provided. A Navy stick grip shall be

installed having a trigger switch for machine gun operation, and a separate

button switch for each rocket launching installation. A switch shall be provided

for the position lights.

E-6b(6). Circuit Protection.

Either appropriate rated fuses or circuit breakers shall be provided in each

circuit for protection.

E-6b(7). Shielding and

Bonding.

E-6b(7)(a). Shielding. A

shielded ignition harness shall be installed on the engine. The magneto switch

shall be of a shielded type.

E-6b(7)(b). Bonding. No bonding

shall be provided.

E-6c. Miscellaneous Equipment

Installation.

E-6c(l). Parachute. The seat

shall be suitable for the use of a seat or back type parachute.

E-6c(2). Safety Belt. A safety

belt of current military type shall be installed.

E-6c(3). Shoulder Harness. A reel

type shoulder harness shall be provided. The reel control shall be accessible to

the pilot.

E-6c(4). Aircraft Cushions. No

cushions shall be provided.

E-6c(5). Map Case. Suitable space

in the cockpit for maps shall be provided. A separate case is not required.

E-6c(6). Fire Extinguisher. No

extinguisher shall be provided.

E-6c(7). Lavatory Facilities.

None shall be provided.

E-6c(8). Heating and Ventilating

System. No heating system shall be provided. Ventilation shall be

provided by adjustable snap type ventilators located at each side of the

windshield.

E-7. Radio Installation. The Bendix

VHF Transmitter and IF Receiver shall be located on the instrument panel. A

mounting for the BC 1335 FM Tactical radio shall be located aft of the cockpit,

and within reach of the pilot for purposes of adjustment. A selective switch

shall allow the use of the microphone and headphones with either radio

installation, and shall be accessible to the pilot.

F. METHOD OF INSPECTION AND TESTS.

F-l. The method of Inspection and test shall be acceptable to the

procuring or evaluation agency.

This is a photo of the M-19. Our

apologies for the quality -- it is a copy of a copy of a copy.

According to our files, the one and only M-19 was designated

X499M - Al's personal airplane. It was seriously damaged when Hal

Rochel, who bought the Mooney factory in 1955, tried - for some

unexplained reason - to take off with a stone tied to the tail. Subsequently, it

was purchased by Bob Purcell of Fort Worth, TX. Beyond that,

its fate is unknown.

See also The Mooney M-19, a

First-hand Look by Elroy "Buck" Hilbert

"The photo is definitely the M-19. The pilot is

Bill Taylor [Mooney's general manager]. Due to the quality of

the picture I cannot be certain as to whether it is as presented to the Military

or repainted and cleaned up as a company run-about. The original was a dull

olive-drab all over and was as ugly as all-get-out."

"The photo is definitely the M-19. The pilot is

Bill Taylor [Mooney's general manager]. Due to the quality of

the picture I cannot be certain as to whether it is as presented to the Military

or repainted and cleaned up as a company run-about. The original was a dull

olive-drab all over and was as ugly as all-get-out."