In Retrospect... Mooney Mite by Jack Cox

No one ever accused Al Mooney of being a slave to convention . . . and his little single place M-18 Mite is living proof. In the late 1940s, the U.S. was awash in airplanes. The government had dumped thousands of World War II airplanes on the civilian market at give away prices and the light plane industry had flooded what was left of its market in a wild orgy of production that saw an astounding 32,000 planes shipped in 1946 - a record that's never even been approached to this day. Yet, in the midst of all this wretched excess, Al Mooney decided what the world needed was a single place, highly efficient little airplane that could be bought for about $1700.

Possessed, as we are, of 20/20 hindsight, it's interesting to speculate how many times Mooney had to suffer through put-downs like, "Shucks, Al, fer them kinda bucks I can buy me three or four brand new BT-13s . . . each full of gas!" Indeed, knowledgeable aviation people have always questioned the existence of a viable market for single place certified airplanes. Almost everyone who ever flew a Mooney Mite thought it was a real blast, but when the time came to plunk down the hard, cold cash, most ended up buying a used two-place of some sort. From 1949 to 1955, only 291 Mites were built and most went to FBOs, who used them as rental planes. As usual, it was only when the little speedsters were sold as used airplanes that they began to impact the private owner market.

Once it was out of production and almost totally in the hands of private individuals, the Mite took on an entirely different character. Over night it became the object of a virtual cult, its devoted owners treasuring the airplane to a degree that transcends any of the normal everyday yardsticks we use to evaluate aircraft. But, once anything becomes a person's hobby, yardsticks no longer matter. The successful pursuit of happiness is all that really counts.

But enough of the whys and wherefores, the fact is Al Mooney did it - went right out and built a fast little single placer, even if the world wasn't beating a path to his door for one.

Al Mooney's first cut at the M-18 (signifying his 18th design) was, from a technical standpoint, even more interesting than the production aircraft that later evolved. He wanted to build his version of "everyman's airplane" . . . which meant, first and foremost, it had to sell for about the same price as a new Ford, Chevrolet or Plymouth . . . about 1700 or 1800 late 40s dollars. The only way, the only prayer he had of pulling that off was to adapt a cheap, mass produced engine of some sort for aircraft use . . . and get it certified by the CAA. Al did a lot of research and was pretty close to choosing an industrial engine (Waukesha or Hercules) when he heard about the new "sheet metal" engine Powel Crosley, Jr. was developing for his tiny postwar automobiles. The engine was a four cylinder development of a single overhead cam six invented by a Californian named Lloyd Taylor that the Navy evaluated for use in driving generators aboard World War II PT boats.

The engine's block consisted of 4 steel tubes for cylinders, sheet metal stampings for cylinder heads, intake and exhaust ports, valve enclosures, water jackets and many other components. In all, 120 or so stampings were utilized, each fitted to the other by crimping, press fits and/or spot welds. When it was all together, copper, in various forms (including paste), was applied to the joints and the block was placed in a furnace at 2060° and held there until everything melded into one. The copper brazed block was then fitted with a 7% pound aluminum crankcase just 3 inches deep, in which was cradled a cast steel, five main bearing crankshaft. The overhead cam was driven by a tower shaft and two bevel gears. Cylinders were protected by a baked on coating of plastic, which inhibited rust. Pistons were of aluminum. The bore was 2.5 inches, the stroke 2.25 inches and the displacement was only 44 cubic inches. That's only a smidgin more than the displacement of just one of the cylinders of a Continental A-65! The compression ratio was 8.2 to 1 and a mighty 26.5 horsepower was alleged to have been developed at 5000 rpm. It was a tiny thing - just over a foot long - and less generator and starter, weighed barely 59 pounds.

Mooney worked out a deal to buy engines from Crosley and set to work modifying one for his new airplane. It was fitted with a 2 to 1 belt reduction unit that utilized 4 Goodyear "wedge" belts, a new development at the time. The automotive ignition and plugs, generator, carb (Tillotson) and 1.8 quart cooling system were retained, the radiator located in a scoop fitted to the belly right under the pilot. As modified, the engine package weighed 101 pounds.

Mooney obtained CAA certification of the engine, which was designated the "Mooney CC46M-2", and proceeded to install it in the new airplane that had been under development during the same time frame. You know what it looked like - the first of the high aspect ratio winged Mooneys with the for- ward swept vertical tail. The mixed construction is also pretty well known: wood wing, tail cone and tail surfaces, all tied into a steel tube cage that formed the cockpit area. A tricycle, retractable landing gear was fitted, actuated mechanically by means of a long lever in the cockpit. Runway shocks loads were absorbed by rubber discs in compression, a Mooney trademark to this day.

Al's last design before the Mite had been the Culver V, which incorporated a patented interconnection between the pitch trim and the flaps, a system called Simpli-Fly ("Before You Buy, Try Simpli-Fly"). A version of it was used on the Mite. As they still do today on the 201 and 231, the Mite's entire tail section pivoted for pitch trim. A little hand crank on the left side of the cockpit tilted the tail forward (or "up") until during the last 1/4 of the crank's travel, it also began lowering the flaps. This simultaneous nose up/flaps down action cancelled out the trim change most other airplanes experience when the flaps are lowered or raised. If you had to make a go- around, a spring in the system permitted some "give" in the trim so that sudden application of throttle would not stand the airplane on its tail.

The M-18 was full of such clever devices. The gear-up warning was an old vacuum type windshield wiper motor mounted in the panel and running off the intake manifold which wagged a red disc right in front of the pilot's nose whenever power was reduced to about 1200 rpm - with the gear still up. Then there was the fuel shut-off valve, positioned so that if left "off", it would be nudged to "on" by application of full throttle. Al had a million of 'em!

Specs included a span of 27 feet, a wing area of 95 square feet and an empty weight of just 460 pounds. At its 700 pound gross weight, the Mite had a wing loading of 7.4 pounds per square foot. Unfortunately its power loading was a rather sickly 28 pounds per horsepower (most light planes are in the 12 to 18 pound area) . . . and therein tells the tale of the Crosley engined Mooney Mite.

One of the best contemporary reports on the Crosley Mite was Max Karant's, which appeared in Flying in December of 1948. Max thought it flew beautifully - once he managed to get it off the ground. It took him over 15 seconds of ground roll - on pavement and into a 20 mph crosswind - to get it flying and then he was stuck with a climb rate of between 180 and 200 fpm. Max, who has never been known to mince his words, laid it on the line. The airplane was grossly underpowered, with "unsatisfactory take-off performance" - in another paragraph he called it "critical". It needed a higher horsepower aircraft engine, he wrote, which would turn it into an "excellent little airplane".

Max also wasn't exactly overwhelmed with the manual gear retraction system . . . making him the first in a long and distinguished line of aviation writers to decry the infamous Mooney "muscle builder" and/or "thumb buster" gear handle that persisted down through the Mark 20 series before finally being replaced by an electric retraction system. Max thought the Crosley Mite's gear handle compromised safety during take-off because the pilot had to momentarily duck his head while reaching forward under the panel to grasp it. Many of Max's recommendations were subsequently incorporated in the Mite (including the name, it seems), but the "thumb buster" endured for another 20 years.

Regarding the name "Mite", it appears to have been coined by Max Karant in the first paragraph of his 1948 Flying article when he wrote, "The Mooney M-18 (I'd call it the Mite) is so tiny that you almost have to 'strap it on' to fly it." Apparently, the airplane had no name prior to that - just the designation M-18. Max's nickname stuck and in all subsequent articles, it is referred to as the "Mite".

With the Crosley engine, the Mite was not a very fast airplane - for the power it was, but not as compared to other light planes of the day. It cruised at 85 mph and topped out at 100. Redline was only 120 mph . . . and the structural load factor was 4.4 G. Economy was the Crosley Mite's long suit. It could be leaned down to around 1.5 gph - and several long distance flights were made on ridiculously small amounts of fuel, including a 1312 mile jaunt in 1950 by Al Mooney, himself, to celebrate his 25th year as an airplane designer.

A half dozen Crosley powered Mites were built and placed in the hands of dealers in California, Florida, Ohio, New York and, of course, Kansas to do a market survey before committing to full production. The answer was quick in coming . . . "It needs more power!" Consequently, Al gave up his goal of a truly low cost airplane and installed a Lycoming O-145.

The results were spectacular. It had been belatedly discovered that though rated at 25 hp as a result of bench testing, most of the Crosleys - as installed in the airplanes - were actually producing only about 17 or 18 horsepower. With the 65 horsepower Lycoming, the little bird became a pocket rocket by comparison.

The numbers say it all:

|

Crosley

|

Lycoming

|

|

|

Empty Weight

Gross Wing Loading Power Loading Top Speed Cruise Climb Rate Absolute Ceiling |

460 lbs.

700 lbs. 7.4 lbs. 28 lbs. 100 mph 85 mph 400 fpm 14,000 ft. |

500 lbs.

780 lbs. 8.2 lbs. 12 lbs. 138 mph 115 mph 1090 fpm 21,300 ft. |

With this model, the M-18L, Al Mooney had himself an airplane and production was soon underway. Through the next seven years, a number of minor improvements were made, things like increasing the fuel capacity and enlarging the canopy, and, ultimately, producing a version with the Continental A-65. There were five model designations in all: the original Crosley powered M-18, the Lycoming 0-145 M-18L and M-18LA, the A-65 powered M-18C and the last of the line, the M-18C-55. 291 Mooney Mites were built of which the M-18C was the most popular model with 120 delivered. The first 226 were built in Wichita and the remaining 65 were built in Kerrville, Texas after Mooney moved the company there in 1953. Al and his brother Art, who was his production ram rod, both resigned from Mooney Aircraft in 1955 and were never associated with the aircraft that bore their names again.

Al Mooney lives in retirement in Texas at this writing. He has been a brilliant and legendary aircraft designer throughout his long career... and usually well ahead of his time.

|

Our Featured Airplane

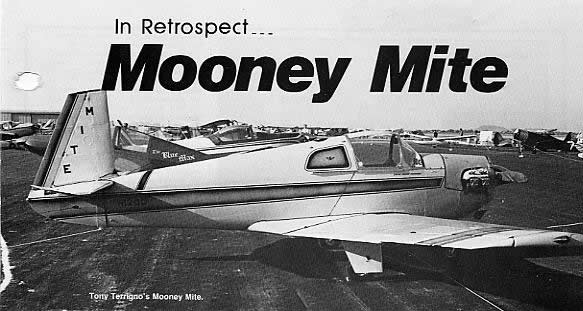

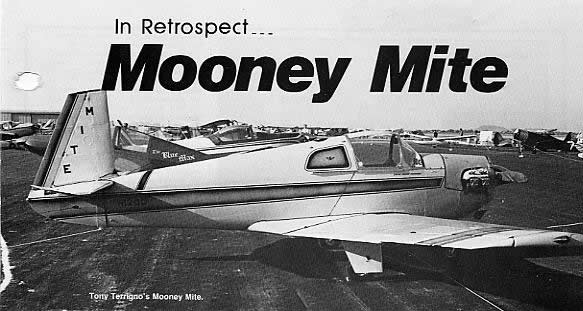

Our featured Mooney Mite is the 81st one built - a 1950 M-18L. It was totally and beautifully restored by its present owner, Tony Terrigno of Buena Park, CA. It is yellow with a dark green "feathered" trim stripe, outlined in black. |

Bought in 1975 as a basket case, it was completely disassembled and rebuilt. Fortunately, most of the wood was in excellent shape and only required some minor rework in the tail cone and some re-gluing of joints. All the old wiring, fuel lines, etc., were replaced; the cockpit was fully insulated and reupholstered; a later model 15 gallon fuel tank was installed; the gear was re-bushed . . . you name it. The Lycoming 0-145 was overhauled, all the cowling was replaced and the nosebowl was rebuilt with a landing light installed.

DuPont enamel was used to paint the airplane and is the only thing Tony says he would do differently the next time around (this is his second Mooney Mite restoration, incidentally). It looks great but is subject to minor cracking in the more flexible areas (fabric). He would use DuPont's acrylic enamel today, he says.

The Mite was flown in August of 1980 and has accumulated 200 hours since the restoration. A shelf full of trophies have been won, including Best Custom Class A (0-80 hp) at Oshkosh last summer. . . and was still raking them in at the Copperstate Fly-In last October when we saw him there.

A native of Youngstown, OH, Tony moved to California in 1954 to go to work as an engineer for Hughes Aircraft. Today, he travels the world for Hughes as a Technical Director of defense system installations. He began flying - on his own - in 1942 and has been at it ever since. Over the years, he has owned a Porterfield, PT-19, Cessna 140 (2 of them), a 172 and has flown many other types, including Stinson SR-9s and 10s, BT- 13s and golden oldies like Waco 10s.

Concurrent with his power plane flying, Tony has been equally involved with soaring. He has been a soaring instructor for the Orange County Soaring Association for 18 years and currently owns a PIK-20D.

Of his Mite, he says, "It's a fun machine, but has its limitations - you have to know them. It's clean and you have to watch your speed in turbulence - especially during fly-bys. Otherwise, it's a nice airplane to own today - a very economical airplane." On his trip to Oshkosh last summer, he had an average ground speed of 118 mph, burning 3.3 gallons per hour.

And I can certainty vouch for the fact that it's a show stopper at fly-ins!

This well-written article by Jack Cox first appeared in the Winter 1983 edition of SPORTSMAN PILOT. Thanks to Bill Vandersande for this material.

May 24, 2000