Wiper Motor Repairs

Magnani Michael, N4094 submitted this report on his experience with repairing his Mite Vacuum Wiper Motor. This device, of course, is what drives the classic Mite "wig-wag" gear warning indicator. The report was so nicely done that we think it will be a good example for others. Here are his words and photos:

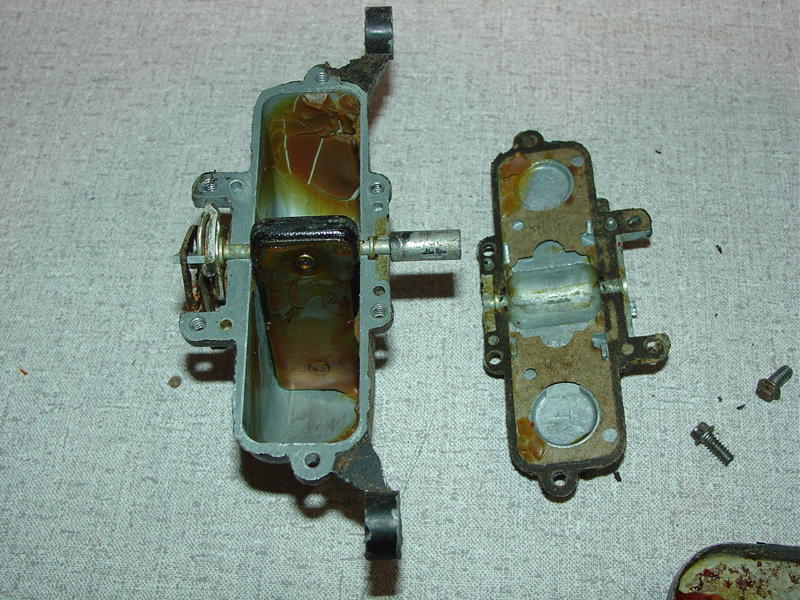

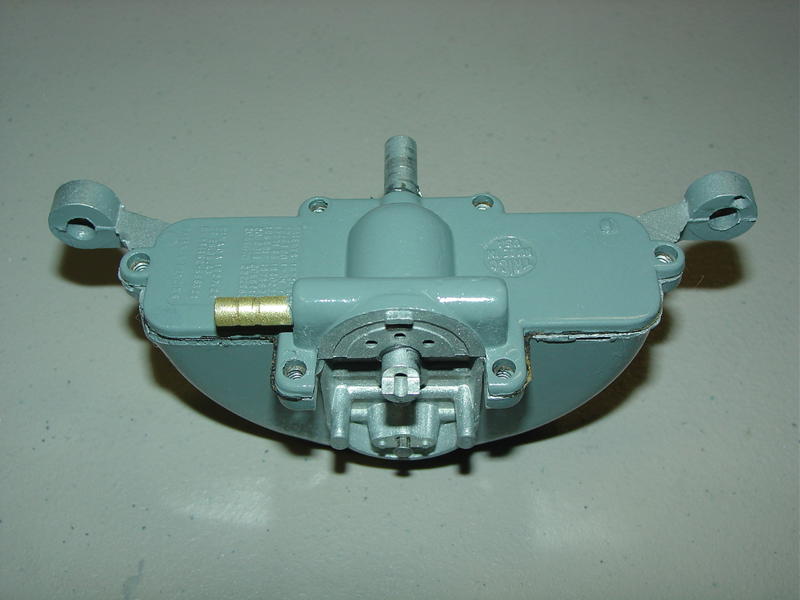

During the course of rebuilding N4094, I bought a vacuum windshield wiper motor from Boyd Maddox to use for the Landing Gear Warning System. The motor had been sitting for well over 50 years and had frozen solid. What follows is a description of taking one apart, cleaning and reassembling it, and some photographs showing the process.

Note: The output shaft is so small in diameter that it can easily be broken if the motor is frozen and you try to force it.

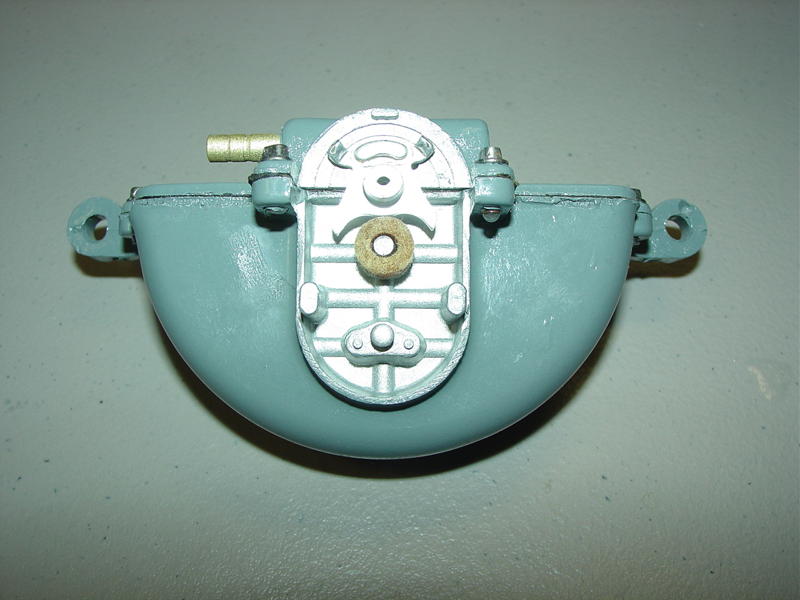

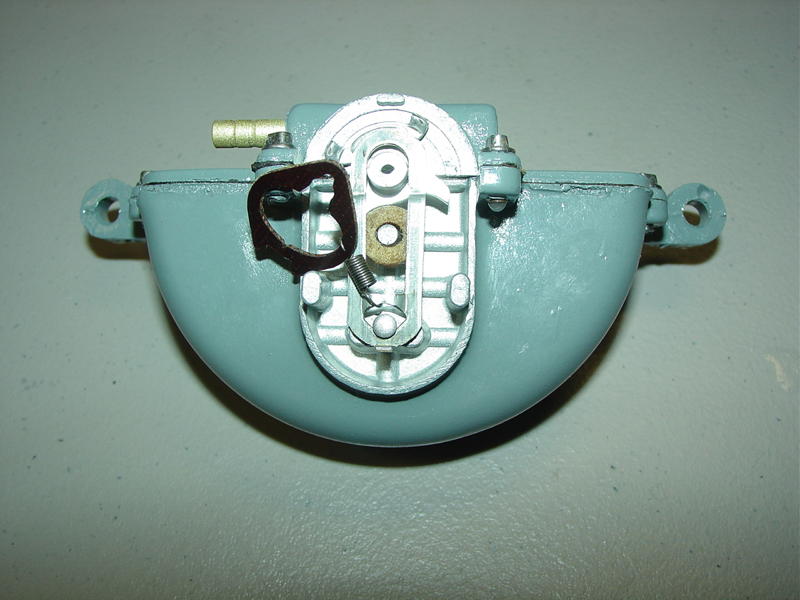

Now you can lift out the paddle assembly out of the vacuum chamber.

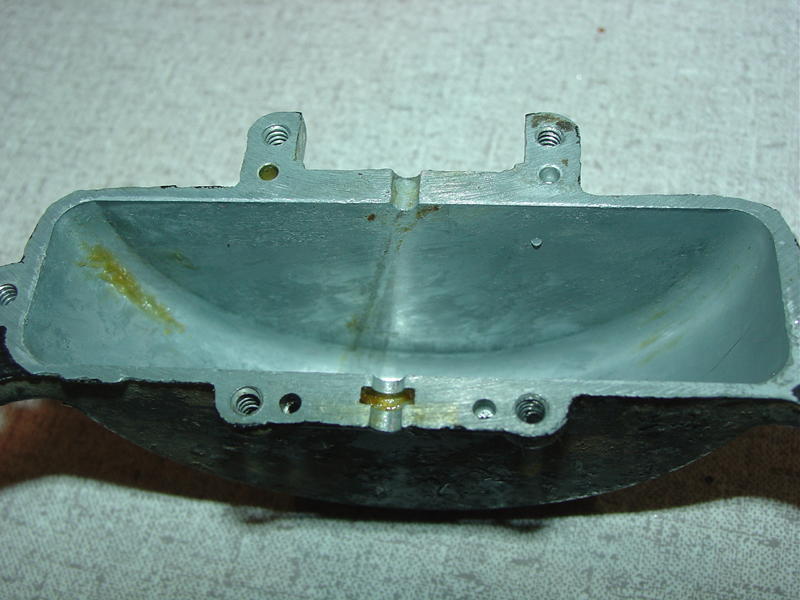

The reason my wiper motor was frozen was because the lubricating oil had totally solidified. Once I cleaned out the oil residue, I could see that corrosion had set in where the paddle had remained in contact with sides and bottom of the chamber. I started with #320 grit sandpaper and wet-sanded the surfaces and worked up to #600. The metal is very soft and polished up pretty quickly.

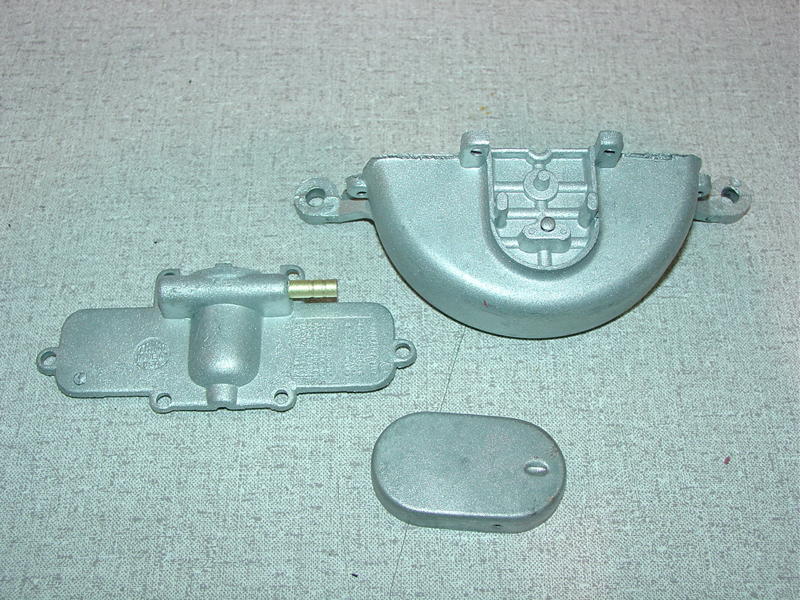

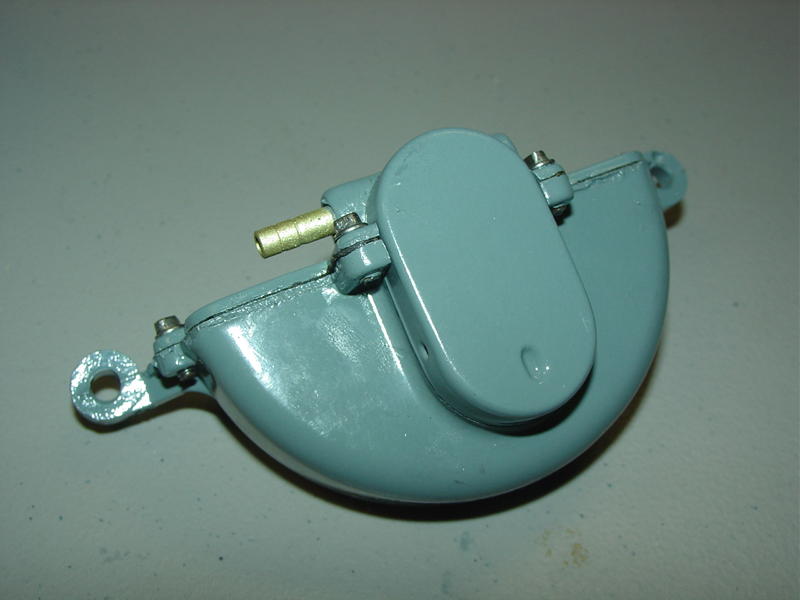

During the clean up process I glass-bead blasted the body, lid and valve mechanism cover and wiped everything down with acetone. I masked off the portions I didn't want painted and sprayed everything else with Tempo A-1105 Medium Gray Aircraft Enamel Spray Paint. For durability, I baked the parts at 250 degrees F for three hours in my little paint oven.

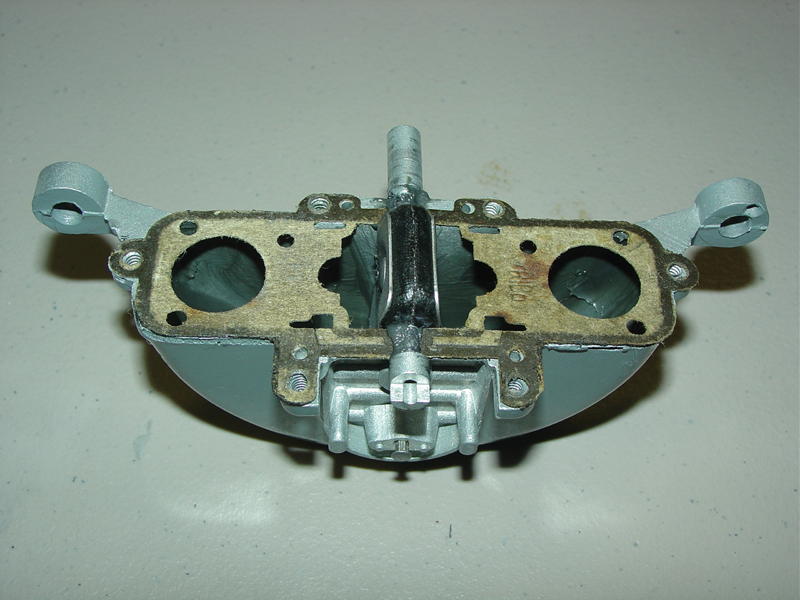

Research on the internet indicated that most people that rebuild wiper motors use a light-weight synthetic grease. I used Aeroshell 33 because I had some in my supply cabinet. I coated the entire chamber lightly, lubricated the paddle and added a pencil-erraser dollop of grease on each side of the paddle for good measure.

Upon re-assembly, I elected not to use any sealant on the paper gaskets in case I had to take it apart again. As it turned out, I didn't have to tear it down again and the paper gaskets turned out to be air tight without any sealant.

Here's a short video taken by my wife's iPhone 4 that shows the operation of the valve mechanism:

I hope this helps remove some of the mystery of the Mooney Mite Landing Gear Warning Actuator.

Mike Magnani

N4094

February 18, 2011