The starting point for the project was CF-LLN, a 650-hour 1953 M-18LA owned by Carmen Pearson of Camrose, Alberta. In 1968, when it failed its annual inspection, CF-LLN was scrapped. The engine and engine mount were removed, including the tubular steel frame back to instrument panel, and sold as a unit to a Mooney Mite builder in Prince Edward Island about 1970. The remainder of this factory Mite was the basis for the homebuilt one.

Here is an outline of the main points in the undertaking:

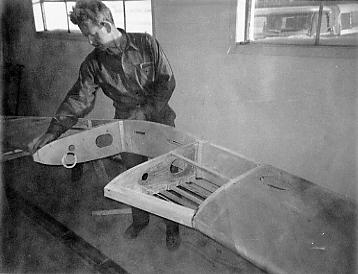

1) Wing: The main spar was salvaged, and the plywood replaced,

front and rear, between left and right landing gear. Also replaced was the "D"

section forward of the spar in the same location. This was all necessary due to

glue separation and badly decomposed wood. All ribs and rear spar were in the

same condition. All structure aft of the main spar were built new with sitka

aircraft wood and aerolite glue or weldwood resorcinal glue. The complete wing

was sheeted with Finland birch plywood and a final cover of very light

fiberglass cloth and endura epoxy paint.

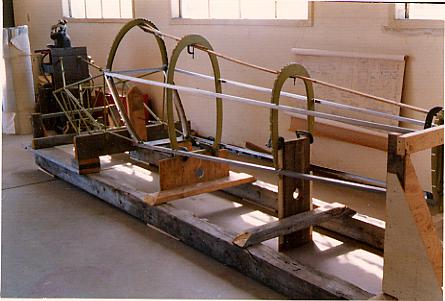

2) Fuselage: The forward fuselage tubing (back as far as the cabin) was salvaged from CF-LLN, but a new Continental engine mount was built. The new rear fuselage "cone" was made of aluminum instead of wood (see photos). Denver says he couldn't have done the job without making use of Fred Quarles' M-18X drawings.

3) Empennage: The fin and horizontal stabilizer were replaced.

4) Controls: The rudder, elevators, flaps and ailerons were found to be in good condition. They were re-covered with ceconite.

5) Engine: The Continental C65 had beenacquired in 1975 from another scrapped Mite, N4139, serial number 306, which Denver had actually flown, at risk, up from Arizona. The engine was top overhauled and fitted with a Mooney exhaust system and Flottorp propeller. A 40 amp. Toyota alternator was mounted and driven by a Chev V-belt pulley on the crankshaft flange. A Cessna Cardinal prop spinner iced the cake. (Denver's account of bringing N4139 up from Tucson will be featured in another article, coming soon).

6) Brakes: Cleveland 5.00x5 wheels and brakes were fitted on modified Mooney M-18 landing gear.

7) Windshield: The standard Mooney M-18 windshield and sliding canopy from CF-LLN were used..

8) Fuel system: There are four fuel tanks holding a total 29 gallons. It has a standard gravity-feed main fuselage tank, along with an auxiliary system consisting of two small wing tanks and a fuselage tank, all connected to a Piper fuel selector and an electric fuel pump which pumps fuel direct to the engine.