Restoration of a Mooney Mite: part I

by Dick Rank

(Reproduced from the Minnesota Flyer

magazine, January 1998)

Dick Rank built a Kitfox on these pages several years ago. Now he's back with a restoration project that he describes as "an ambitious undertaking but a very pleasurable learning experience. "

It was just another average June Friday down in Atlanta, hot and humid. I was there visiting a very special friend and renewing other connections, and during a lull in activities, I drifted over to Peachtree Dekalb Airport, where I started flying lessons nine years ago. PDK is about as busy as Flying Cloud, my home base, and a nice place to find hangar talk and good coffee. One spot there always draws me back. Ben Epps, the son of Georgia aviation pioneer Ben Epps Sr., has his aviation shop there. I say "aviation shop" because in about 1,000 square feet of dusty and crowded floor space in a World War II naval aviation hangar, almost every known activity in aircraft construction has occurred, from restoring 1910 homebuilts to recovering or repairing Stearmans, Pitts, Decathlons and Franklin engines. Ben knows it all and has done it all.

Ben is now 81 years old and still doing almost all of it. I know he has forgotten more about airplanes than I will ever know. Because he is such a gentleman and the best of aviators, I have to stop in when close by. When stepping into the hangar, one steps back into aviation of the 30s and 40s.

Ben remembers barnstorming flights in Ford Trimotors, and his stack of logs shows thousands of hours flying for Western Air Lines. You should also know that Ben flew C-46s over the Hump in the China/India theater during the Big One and has some incredible true stories to tell of those times in aviation.

On this recent Friday, I noticed a small, faded yellow aircraft in the hangar as Ben offered a cup of coffee. It was a 1950 Mooney Mite, serial No. 79, and it looked to be in fair shape. The low-winged Mite comes as close to a personal fighter of any antique priced at less than warbird prices, providing you don't mind a cruise speed of 115 mph. It has room for one medium-sized person plus a shave kit, but on the plus side, it has retractable gear, a bubble canopy, flaps and a great panel.

|

| The deal is done: Dick Rank, right, buys. |

I asked Ben a fateful question: "What's the story on that Mooney?" And he uttered the fateful words, "I'm selling it." Apparently he saw it being stored outside for a few months and offered to buy it to save it, improve its appearance and perhaps increase the personal checking account just a little. By this time he knew exactly what needed doing to restore it to airworthiness and to make it something of beauty to appreciative aviators.

Naturally, I had to examine it to increase my knowledge of aviation. After all, I hadn't seen a Mooney Mite before. As I walked; around it, climbed under it and stretched for a look into that neat cockpit, wise old Ben was making comments such as, "Those wooden wings are really easy to fix if they need it. I could do it in a week or two. And that Lycoming 65 is really a smooth and sweet little engine. Runs good."

It is truly amazing how easy it is to sell something to someone who is driven by subconscious urges to own it. Before the morning was over, I had pored through the papers, the factory manual and other assorted documents, talked myself into the idea that I needed yet another wintertime project and made Ben an offer that was slightly below his asking price. I even temporarily talked myself into the notion that if he refused, my life might be a little easier without the airplane. That lasted all of two hours, and then I began to believe that another prospective buyer had lots of money and had bought it outright after I left.

|

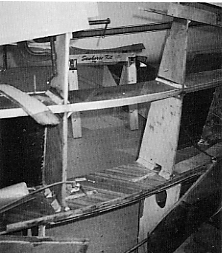

| Fifty years of heat and moisture are too much for the joint. |

I remained in a funk of distracted worry until the next morning, when my girlfriend, now my wife, suggested that I call Ben to settle the matter. We decided to look at the Mite again, and an hour later I made a deal that made us both happy. I showed the little single-seater to Nancy, and her question was, "Where are you going to sit, Dick?" She flies too.

Over the past several years I had held a quiet hope that I could work alongside Ben to learn some of what he knows and experience the enjoyment of restoring an aircraft taking me beyond the skills I needed to build my Kitfox. In 24 hours it all came together. Restoring the Mite will be an ambitious undertaking but a very pleasurable learning experience. Flying it will be icing on the cake.

***

It was only a couple of weeks ago that I first saw the little yellow Mooney Mite. It looks very different now. The wing is off and up on edge in wing racks; the fabric is gone and the insides are open for all to see. The fuselage rests comfortably on a roll-around cradle with casters salvaged from damaged grocery carts. That was yet another of Ben's ideas. He is a vast source of little tricks and methods to get the job done right. Ben continues to be my guide and mentor to ensure that things get done properly.

Now it was my aircraft, and any problems were my problems. The moment of truth had arrived. We were in the "discovery" phase of restoring a wooden aircraft. It was truly a discovery process as we tore off old fabric to see the condition of that all-important wooden structure so cleverly engineered and assembled 45 years ago by the Mooney boys. Much to my satisfaction, there were no surprises. The main spar looked good all the way to the tips, but as we expected, the smaller and shorter laminated spruce rear spar would have to be replaced. It was badly rotted from moisture. A few smaller pieces showed the results of exposure to water, requiring more replacement work. Nevertheless, I was happy because I could see that the project was manageable.

Ben went straight to work. He obtained a flat, wide, eight foot piece of quarter-inch steel and with it built a bending jig for the two parts of the laminated rear spar. That critical curve in the spar had to match the dihedral for both wings. He returned from his storage loft with a beautiful, long two-by-six of Sitka spruce, worth its weight in gold because it is aircraft quality, it has seasoned for a number of years and it is absolutely free of defects. In a few days we had an exact replica of the rear spar ready. It was laminated to maximize strength and sealed with webs of mahogany plywood for stiffness. The process was not without its problems. Our first try produced a spar with uneven surfaces, so changes were made in the jig. The second try is now a thing of beauty, light and strong, a perfect duplicate of the original without the delamination and rot.

|

| Ben Epps glues the rear spar. |

I must say that I'm constantly amazed at how helpful the network of flyers and builders can be. Once I arrived back home in Minnesota for a time, I quickly found advice and help from fellow Minnesotan Duane Flackbarth, who, with Durber Allen, won a blue ribbon two years ago at Oshkosh for their beautifully rebuilt Mooney Mite. Duane and I met at the Anoka County Airport during Aviation Days. Right there in front of me was a fine example of the Mite, and I spent a lot of time looking and asking questions.

Surprising numbers of pilots have flown the Mite, and some have explained its flight characteristics to me. Bill Moga at American Flight gave me a copy of the original marketing brochure for the Mite. That helped to establish the original color scheme. Still others helped by locating part sources and engines.

In November of last year, I went back to Atlanta for the winter, prepared to work full-time for six months on the Mite. Ben explained to me how, during my absence, a gentleman had walked into the shop one day and seemed especially fascinated with the Mite project. He asked lots of questions, and Ben finally figured out that he was talking to the chief executive officer of Mooney Aircraft. He made it clear that he wants progress reports and pictures. A small and wonderful world, this aviation community of ours.

More exploration revealed that the wing needed more work than we originally thought. Many small wooden components required replacement, and some of the plywood skin would need to be redone. But I knew that eventually we would lay the wing out and begin covering with fabric. Restoration is easier when you only look ahead two or three days. For the big rebuild jobs, discouragement lies just around the corner.

|

| New rear spar and butt ribs. |

Once the one-piece wing is repaired and all joints are reglued, it will be time to get out the pinking shears, the Stits fabric glue and the covering fabric. While building my Kitfox, I was somewhat doubtful about my abilities for the covering process, but I found it to be very rewarding and fun, so I look forward to covering a traditional wooden wing. The wing will be as good or better than new, the Mite can be flown with confidence and this owner will know a lot more about building wooden aircraft in a few months. And that makes for a very good life.

Let's see. Do Mooney Mite pilots wear goggles and white scarves? After all, it is a poor man's fighter - low wings, retractable gear, bubble canopy and all. Enough dreaming. Back to work or it will never get in the air.

Next page (A Mite Bit of Work: Part II)

Our thanks to Dick Coffey and the Minnesota Flyer magazine.

October 20, 2000